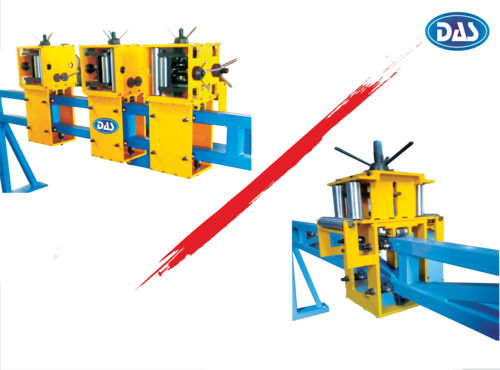

Tension Stands

Tension Stands Specification

- Product Type

- Tension Stand

- General Use

- Wire & Cable Manufacturing Line

- Material

- Mild Steel

- Type

- Vertical Tension Stand

- Weight (kg)

- 120-400 kg

- Computerized

- No/Optional

- Automatic

- Semi-Automatic

- Control System

- PLC Based/Manual

- Power Source

- AC Electric

- Power Consumption

- 1-2.5 kW

- Coil Diameter

- Max 800 mm

- Winding Head

- Fixed/Adjustable

- Winding Speed

- 10-250 m/min

- Winding Spindle

- Solid Alloy/Steel

- Air Pressure

- 6 bar (87 psi)

- Drive Type

- Pneumatic/Hydraulic/Manual

- Voltage

- 220/380/415 V

- Dimension (L*W*H)

- 1100x700x1650 mm

- Feature

- Sturdy Construction, Adjustable Tension, Smooth Performance

- Color

- Industrial Grey & Yellow

- Tension Range

- 0.5 kg to 20 kg adjustable

- Noise Level

- <70 dB

- Operating Temperature

- Up to 60°C

- Mounting Type

- Floor Mounted

- Safety Features

- Overload Protection, Emergency Stop

- Surface Treatment

- Powder Coated

- Roller Material

- PU Coated, Hardened Steel

- Application

- Wire Drawing, Cable, Rod, or Strip Winding Lines

Tension Stands Trade Information

- Payment Terms

- Letter of Credit (L/C), Cheque

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Tension Stands

Tension Stands

Outfitted with an advanced infrastructure, we are the most prominent supplier, manufacturer and exporter of Tension Stands (Custom Designed). This is appreciated and demanded for it's optimum quality, dependability, easy installation, low maintenance requirements, reliability, unmatchable performance, longer functional life, and seamless quality. It is made in tandem with international standards using modern machines and quality materials. Therefore, we are acknowledged as noted supplier, manufacturer and exporter of Tension Stands (Custom Designed). We are mainly deal this product in Hyderabad & it's near by areas.

Note: We also deliver this in promised time frame.

Precision Tension Control for Industrial Applications

Our tension stands deliver precise adjustable tensionessential for achieving consistent results in wire and cable manufacturing. The sophisticated control systems, either manual or PLC-based, help maintain uniformity throughout the winding process. Designed for accuracy in demanding environments, these stands accommodate diverse materials and production needs, ensuring reliable output and reduced downtime.

Constructed for Durability and Safety

Built using mild steel with a powder-coated finish, our stands are engineered for heavy-duty industrial use. Safety features like overload protection and emergency stop functions are integrated for operator security. With sturdy rollers available in PU-coated or hardened steel, the units operate quietly and efficiently, helping to maintain a safe and organized workspace.

Versatility to Fit Your Production Needs

Whether you need manual, pneumatic, or hydraulic drives, our tension stands offer the flexibility to integrate seamlessly into new or existing lines. The adjustable winding heads and solid alloy or steel spindles cater to various coil diameters up to 800 mm. This versatility makes them a smart choice for exporters, manufacturers, and suppliers looking to enhance wire and cable production.

FAQs of Tension Stands:

Q: How is the tension adjusted on these vertical tension stands?

A: The tension can be adjusted from 0.5 kg to 20 kg using manual, pneumatic, or hydraulic mechanisms, depending on the configuration chosen. The control system may be manual or PLC-based, allowing for precise and consistent adjustment during wire or cable winding.Q: What materials can be processed with this tension stand?

A: This stand is suitable for processing wires, cables, rods, or strips, making it ideal for various winding lines in the wire and cable manufacturing industry. The robust construction and adjustable features accommodate a range of materials and production requirements.Q: When should I use a PLC-based control system versus manual controls?

A: A PLC-based control system is recommended when automated, high-precision operations are required, especially for larger production volumes. Manual controls are suitable for simpler setups, lower volumes, or when flexible manual intervention is preferred.Q: Where can these tension stands be installed, and what is the mounting type?

A: These tension stands are designed for floor mounting and can be installed in wire drawing, cable, rod, or strip winding lines within industrial facilities. Their compact dimensions and adjustable features make them suitable for integration into new or existing production environments.Q: What safety features are included to protect operators and equipment?

A: Key safety features include overload protection and an emergency stop system. These functions help prevent damage to the stand and the product being processed, while also ensuring the safety of operators during operation.Q: How does the winding process benefit from the adjustable tension and solid construction?

A: Adjustable tension ensures uniform winding and minimizes wire breakage or deformation during the process. The sturdy, powder-coated mild steel construction, combined with durable rollers, provides consistent performance, reduced vibration, and extended equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Distribution Transformers Category

Rectangular Former

Color : Silver Grey

Drive Type : Electric

Product Type : Rectangular Coil Former

Feature : Other, High Precision Forming, Robust Construction, Easy Operation

Computerized : Yes

Manual LV Coil Winding Machine

Color : Blue & Black

Drive Type : Other, Hand Operated

Product Type : Low Voltage Coil Winding Machine

Feature : Other, Compact Design, Rust Resistant, Easy Operation

Computerized : No

Manual Operated Hv Coil Winding Machine

Color : Blue & Silver

Drive Type : Other, Manual Hand Operated

Product Type : HV Coil Winding Machine

Feature : Other, Durable, Smooth Operation, Low Maintenance

Computerized : No

Semi Automatic Hv Coil Winding Machines

Minimum Order Quantity : 1 Piece

Color : Blue

Drive Type : Electric

Product Type : Semi Automatic Hv Coil Winding Machines

Feature : High Precision

Computerized : No

Send Inquiry

Send Inquiry