Manual Operated Hv Coil Winding Machine

Manual Operated Hv Coil Winding Machine Specification

- Product Type

- HV Coil Winding Machine

- General Use

- Winding High Voltage Transformer Coils

- Material

- Mild Steel Frame, Steel Spindle

- Type

- Manual Winding Machine

- Weight (kg)

- Approx. 45 kg

- Computerized

- No

- Automatic

- No

- Control System

- Mechanical Counter

- Power Source

- Manual (Hand Operated)

- Coil Diameter

- Up to 350 mm

- Winding Head

- Single

- Winding Speed

- Up to 100 RPM (Depends on Hand Movement)

- Winding Spindle

- Heavy Duty Steel

- Air Pressure

- Not Required (Manual Operation)

- Drive Type

- Manual Hand Operated

- Dimension (L*W*H)

- Approx. 650 mm 350 mm 480 mm

- Feature

- Durable, Smooth Operation, Low Maintenance

- Color

- Blue & Silver

- Bed Type

- Heavy Cast Iron

- Noise Level

- Silent

- Max Coil Width

- Up to 250 mm

- Rotation Direction

- Bidirectional (Manual Reversal)

- Wire Gauge Range

- 0.2 mm to 3.0 mm

- Application Industry

- Transformer Manufacturing, Electrical Workshops

- Reset Counter

- Yes

About Manual Operated Hv Coil Winding Machine

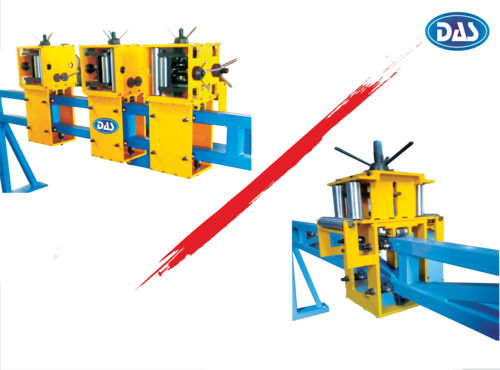

Manual Operated Hv Coil Winding Machine

Our Manual Operated H.V Coil Winding Machines are designed with accurate dimensions, construction, optimum performance, high strength, efficiency and more. As a reputed manufacturer, exporter and supplier we provide these in various specifications and sizes as per the clients requirements. Manufactured under the observation of expert personnel, these are in complete compliance with the industry defined norms. Manual Operated H.V Coil Winding Machines can be availed at industry leading prices and within the promised time scale.

Specifications:

| Model | Winding Speed | Possible winding length-mm | Power K.W |

|---|---|---|---|

| DMHW-2H | 0-300 | 300 | 1.5 |

| DMLW-3H | 0-300 | 400 | 2.2 |

Exceptional Build Quality & Durability

Constructed with a heavy cast iron bed and a robust mild steel frame, this coil winding machine stands out for its resilience and longevity. Its heavy-duty steel spindle ensures stability during manual operation, while the ergonomic design provides both durability and comfort, making it suitable for demanding industrial use in transformer workshops across India.

Versatile and Efficient Manual Operation

Capable of winding wire gauges from 0.2 mm up to 3.0 mm, this machine adapts to various coil requirements. The hand-operated design, bidirectional winding, and mechanical counter allow for controlled winding speedsup to 100 RPM based on hand movementwithout any noise or dependency on external power, making it cost-effective and versatile.

Ideal for Electrical and Transformer Applications

Purpose-built for tasks in transformer manufacturing and general electrical workshops, this manual winding machine excels in high voltage coil applications. Its silent operation, simple mechanical controls, and easy maintenance make it an advantageous tool for exporters, manufacturers, and suppliers seeking dependable coil winding performance.

FAQs of Manual Operated Hv Coil Winding Machine:

Q: How does the manual HV coil winding machine operate?

A: The machine is powered solely by hand, using a manual hand crank to rotate the coil. Operators can change winding direction manually, offering full control over the winding process without the need for electricity or air pressure.Q: What types of wires can be used with this winding machine?

A: It is compatible with wire gauges ranging from 0.2 mm to 3.0 mm, making it versatile for various high voltage coil requirements in transformer manufacturing and electrical workshops.Q: When is this machine most beneficial to use?

A: This machine is most advantageous when power supply is unavailable or limited, or in environments where low operational noise, portability, and manual control are preferred, such as on-site transformer repairs or small-batch coil production.Q: Where can this coil winding machine be used?

A: Designed for transformer manufacturing, electrical repair workshops, and technical institutes, it is well-suited to Indian export markets and suppliers seeking reliable manual winding equipment.Q: What is the process of winding coils with this machine?

A: The user secures the coil form onto the heavy-duty spindle, threads the wire through appropriate guides, sets the mechanical counter, and rotates the hand crank at a chosen speed and directionreversing manually as required. The mechanical counter tracks the number of windings for precision.Q: What are the primary benefits of using this manual coil winding machine?

A: Its main advantages include silent operation, low maintenance requirements, portability, durability due to heavy construction, no need for electrical or pneumatic power, and precise coil winding facilitated by a mechanical counter.Q: Can this machine be easily moved or installed in different locations?

A: Yes, weighing approximately 45 kg and featuring compact dimensions (650 mm x 350 mm x 480 mm), it is relatively portable for movement between workstations or job sites as needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Distribution Transformers Category

Tension Stands

Drive Type : Other, Pneumatic/Hydraulic/Manual

Color : Industrial Grey & Yellow

Computerized : Other, No/Optional

Automatic : Other, SemiAutomatic

Product Type : Tension Stand

Rectangular Former

Drive Type : Electric

Color : Silver Grey

Computerized : Yes

Automatic : Yes

Product Type : Rectangular Coil Former

Manual LV Coil Winding Machine

Drive Type : Other, Hand Operated

Color : Blue & Black

Computerized : No

Automatic : No

Product Type : Low Voltage Coil Winding Machine

Fully Automatic HV Coil Winding Machines

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Color : Blue/White

Computerized : No

Automatic : Yes

Product Type : Fully Automatic HV Coil Winding Machines

Send Inquiry

Send Inquiry