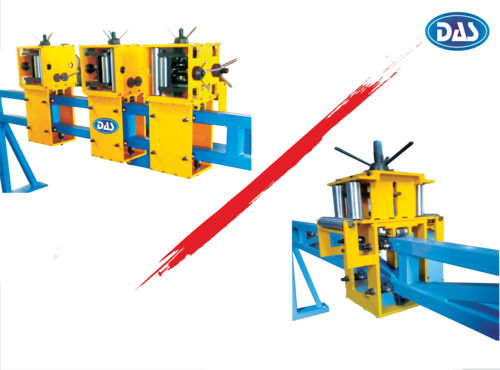

Rectangular Former

Rectangular Former Specification

- Product Type

- Rectangular Coil Former

- General Use

- Forming and shaping of transformer coils

- Material

- Mild Steel / Alloy Steel

- Type

- Automatic Coil Winding Former

- Weight (kg)

- 350

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Coil Diameter

- Up to 500 mm

- Winding Head

- Single/Double Available

- Winding Speed

- 100-600 RPM

- Winding Spindle

- Heavy Duty Steel

- Air Pressure

- 5-7 Bar

- Drive Type

- Electric

- Voltage

- 230/380V, 50/60Hz

- Dimension (L*W*H)

- 1200 x 800 x 1350 mm

- Feature

- High Precision Forming, Robust Construction, Easy Operation

- Color

- Silver Grey

About Rectangular Former

High Precision and Robust Build

Engineered for both dry type and oil-immersed transformer coils, this rectangular former offers exceptional accuracy (0.1 mm) and a robust structure, ensuring reliable daily operation. Heavy-duty steel spindles support longevity, while the powder-coated finish resists corrosion, giving you a lasting and dependable machine.

Advanced Control and Automated Operation

A PLC control system enables streamlined, user-friendly, and fully automated coil forming processes. With a single or double winding head, computerized controls, and easy maintenance, you can achieve consistent coil shaping at variable speeds (100600 RPM) with minimal operator intervention.

Versatile and Efficient Performance

Capable of handling coils with wider diameters and faster cycle times, this automatic coil winding former supports transformer production needs for manufacturers and exporters. With a moderate power consumption and low noise output, it is designed for efficiency and operator comfort.

FAQs of Rectangular Former:

Q: How does the rectangular former enhance coil forming accuracy?

A: The machine operates with a forming accuracy of 0.1 mm, ensuring each transformer coil meets strict dimensional specifications. Its PLC-controlled system and robust construction help maintain consistency throughout repeated production cycles.Q: What is the recommended operating environment for this coil winding former?

A: This equipment functions optimally in temperatures ranging from 5C to 45C and requires an air pressure between 5-7 bar. Its surface is powder coated to withstand a variety of manufacturing settings, making it suitable for industrial use in different regions of India.Q: When should manufacturers consider using this automatic rectangular former?

A: Manufacturers should utilize this machine when high precision, automated coil winding, and efficient production cycles are required, especially for dry type and oil-immersed transformer coils ranging up to 600 mm in width.Q: Where can this former be effectively implemented?

A: The former is ideally suited for transformer manufacturing facilities, coil winding workshops, and industrial production lines, particularly for exporters, manufacturers, and suppliers seeking quality and repeatability in coil forming.Q: What is the typical process for coil forming with this machine?

A: The process starts with setting the desired coil parameters on the PLC interface, followed by loading the material onto the heavy-duty spindle. The automated system then forms the coil accurately within a 30-60 second cycle, producing consistent results with minimal supervision.Q: How does the coil former benefit the end user?

A: Users benefit from high precision forming, robust and durable construction, energy-efficient operation, and easy-to-use computerized control. Low maintenance requirements and a quiet working environment further enhance productivity and operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Distribution Transformers Category

Tension Stands

Drive Type : Other, Pneumatic/Hydraulic/Manual

Color : Industrial Grey & Yellow

Computerized : Other, No/Optional

Product Type : Tension Stand

Feature : Other, Sturdy Construction, Adjustable Tension, Smooth Performance

Manual LV Coil Winding Machine

Drive Type : Other, Hand Operated

Color : Blue & Black

Computerized : No

Product Type : Low Voltage Coil Winding Machine

Feature : Other, Compact Design, Rust Resistant, Easy Operation

Manual Operated Hv Coil Winding Machine

Drive Type : Other, Manual Hand Operated

Color : Blue & Silver

Computerized : No

Product Type : HV Coil Winding Machine

Feature : Other, Durable, Smooth Operation, Low Maintenance

Fully Automatic HV Coil Winding Machines

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Color : Blue/White

Computerized : No

Product Type : Fully Automatic HV Coil Winding Machines

Feature : High Precision

Send Inquiry

Send Inquiry