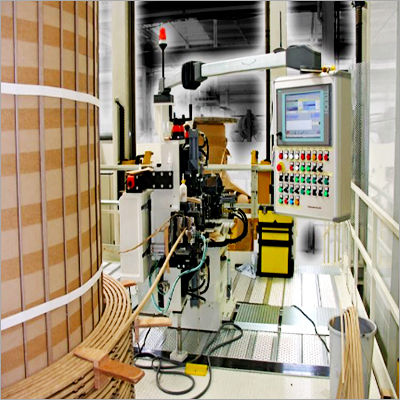

Vertical Winding Machines

Vertical Winding Machines Specification

- Product Type

- Vertical Winding Machine

- General Use

- Winding of Coils, Wire, and Filaments

- Material

- Mild Steel, Aluminium, and High-Grade Components

- Type

- Automatic

- Weight (kg)

- 1200-1500 Kg (Depending on Model)

- Computerized

- Yes

- Automatic

- Fully Automatic Operation

- Control System

- PLC Controlled with Touch Screen Interface

- Power Source

- Electric

- Power Consumption

- 4-12 kW (Model Dependent)

- Coil Diameter

- Up to 1600 mm

- Winding Head

- Single / Multi-head Options

- Winding Speed

- Up to 1200 RPM

- Winding Spindle

- High Precision Balanced Spindle

- Air Pressure

- 6 bar (approx.)

- Drive Type

- Servo / AC Motor Driven

- Voltage

- 380-440 V AC, 3 Phase

- Dimension (L*W*H)

- 2200 x 1400 x 2000 mm (Typical)

- Feature

- High Efficiency, Low Maintenance, Digital Counter, Emergency Stop

- Color

- Industrial Blue / White

- Safety System

- Automatic Shutoff and Safety Guards

- Noise Level

- Less than 70 dB

- Core Clamping

- Hydraulic or Manual Clamping

- Wire Size Range

- 0.1 mm to 4.0 mm

- Cooling System

- Integrated Fan and Air-Cooled Motor

- Display

- HMI Color Touch Panel

- Maximum Coil Width

- Up to 700 mm

- Layer Traverse System

- Servo-Based Precision Traverse

About Vertical Winding Machines

- These are built to perfection and in accordance to international norms of quality.

- Hence, these are extensively used in textile industries.

- Prior to dispatch, these are carefully tested and assessed for any defects or flaws.

Technical Specifications:

| Model | Capacity in Tons | Winding Dia.In mm | Winding Speed in RPM | Lift Stroke in mm | Connected Power In KW | Torque on spindle N-Mt |

|---|---|---|---|---|---|---|

| D-VW5T-2500 | 5 | 2000 | 0-15;0-30 | 2500 | 9.5 | 3360;1680 |

| D-VW10T-3100 | 10 | 3200 | 5,10,20 | 3100 | 22 | 14100;7050;3525 |

Unmatched Precision and Control

These machines utilize servo-based, PLC-controlled systems for accurate and repeatable winding patterns. With a user-friendly HMI touch panel, operators can manage parameters effortlessly, ensuring precise layer and traverse control for different coil specifications. The high-precision balanced spindle and digital counter further enhance winding accuracy and consistency.

Advanced Safety and Ergonomics

Operator safety is a priority with automatic shutoff, emergency stop features, and comprehensive safety guards. Hydraulic or manual core clamping offers secure handling of coils, while the noise level is maintained below 70 dB for a comfortable working environment. The robust construction and low maintenance requirement guarantee reliable performance over extended use.

Versatile Application and Efficiency

Supporting a wide range of coil sizes and wire materials from mild steel to aluminium these machines are suited for electrical, transformer, and industrial coil production. Integrated cooling systems and energy-efficient (4-12 kW) operation ensure sustained high-speed winding up to 1200 RPM, maximizing output while minimizing operational downtime.

FAQs of Vertical Winding Machines:

Q: How does the servo-based precision traverse system benefit the winding process?

A: The servo-based precision traverse system provides exact control over the placement and layering of wires or filaments, resulting in tightly and uniformly wound coils. This technology minimizes manual adjustments and enhances repeatability, ensuring high-quality output with each production cycle.Q: What are the safety mechanisms integrated into these vertical winding machines?

A: These machines are equipped with automatic shutoff, emergency stop functionality, and robust safety guards that protect operators from accidental contact with moving parts, ensuring overall workplace safety during operation.Q: When and where are these winding machines typically used?

A: Vertical winding machines are primarily used in industrial manufacturing environments such as electrical, transformer, and filament production facilities. They are ideal when precise and high-speed coil winding is required, particularly for large coil sizes up to 1600 mm in diameter.Q: What materials can be wound using this machine, and what is the process?

A: These machines can wind wires made of mild steel, aluminium, and similar conductive materials. The fully automatic, computerized process involves feeding the wire through a controlled guide, using servo-driven traverse and spindle systems for layered winding according to programmed specifications.Q: How does the integrated cooling system impact machine performance during operation?

A: The cooling system, consisting of a fan and air-cooled motor, maintains optimal operating temperatures even during prolonged high-speed winding. This prolongs machine life, prevents overheating, and ensures consistent performance.Q: What are the main benefits of using PLC-controlled touch screen interfaces in these machines?

A: PLC-controlled touch screen interfaces simplify machine setup and monitoring, allow for easy adjustments to winding parameters, and provide real-time operational feedback, which all contribute to improved process efficiency and reduced human error.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Power Transformers Category

Roll Type Tension Stand

Voltage : 415 V AC

Power Source : Electric

Product Type : Roll Type Tension Stand

Feature : Other, Consistent Tension Control for Accurate Winding

Computerized : Yes

Affordable Vertical Winding Machines

Voltage : 220240 V

Power Source : Electric

Product Type : Vertical Winding Machine

Feature : Other, Easy Operation, Sturdy Construction, Energy Efficient

Computerized : Yes

Power Winder Machines

Minimum Order Quantity : 1 Piece

Voltage : 220 Volt (v)

Power Source : Electric

Product Type : Power Winder Machines

Feature : High Precision

Computerized : No

Horizontal Winding Machines

Minimum Order Quantity : 1 Piece

Voltage : 220 Volt (v)

Power Source : Electric

Product Type : Horizontal Winding Machines

Feature : High Precision

Computerized : No

Send Inquiry

Send Inquiry