Affordable Vertical Winding Machines

Affordable Vertical Winding Machines Specification

- Product Type

- Vertical Winding Machine

- General Use

- Coil Winding for Electrical Industry

- Material

- Mild Steel & Alloy

- Type

- Vertical

- Weight (kg)

- 450

- Computerized

- Yes

- Automatic

- Semi-Automatic/Automatic

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 2.5 kW

- Coil Diameter

- Up to 600 mm

- Winding Head

- Single / Double

- Winding Speed

- 1000-1500 rpm

- Winding Spindle

- Hardened Steel

- Air Pressure

- 6-8 Bar

- Drive Type

- Servo Motor Driven

- Voltage

- 220-240 V

- Dimension (L*W*H)

- 1200x800x1700 mm

- Feature

- Easy Operation, Sturdy Construction, Energy Efficient

- Color

- Blue & Silver

- Cooling System

- Air Cooling

- Installation Type

- Floor Mounted

- Lubrication

- Automatic Lubrication System

- Application

- Textile, Electrical, Industrial Winding

- Display Type

- Digital Display

- Suitable Wire Size

- 0.2 - 4 mm

- Safety Features

- Emergency Stop, Overload Protection

- Max Bobbin Length

- 550 mm

- Noise Level

- <65 dB

About Affordable Vertical Winding Machines

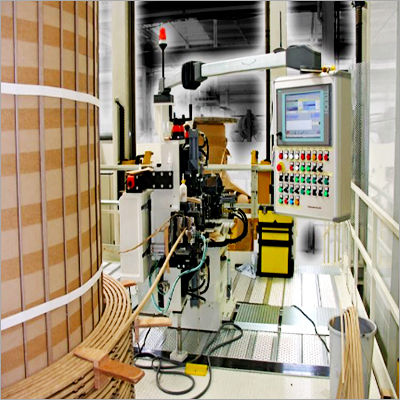

Affordable Vertical Winding Machines

Banking upon our their market understanding and the vast experience of our accredited professionals, we have ranked ourselves as a trusted supplier, manufacturer and exporter of Affordable Vertical Winding Machines. These are made under the guidance of experienced professionals using modern technology and quality assured raw materials. Hence, our offered Affordable Vertical Winding Machines are widely in demand.

Features:

- Optimum strength

- Reliability

- Seamless quality

- Longer functional life

- Stability

- Easy installation

- Minimal maintenance requirements

- Unmatchable performance

- Simple operation

- Rugged construction

Technical Specifications:

| Model | Capacity in Tons | Winding Dia.In mm | Winding Speed in RPM | Lift Stroke in mm | Connected Power In KW | Torque on spindle N-Mt |

|---|---|---|---|---|---|---|

| D-VW5T-2500 | 5 | 2000 | 0-15;0-30 | 2500 | 9.5 | 3360;1680 |

| D-VW10T-3100 | 10 | 3200 | 5,10,20 | 3100 | 22 | 14100;7050;3525 |

Precision Engineering for Versatile Winding

Engineered for the electrical industrys evolving needs, these vertical winding machines deliver exceptional precision for coils up to 600 mm in diameter. Whether semi-automatic or fully automatic, their servo-driven, PLC-based controls allow for meticulous customization, while the sturdy frame ensures lasting performance. From single to double winding heads, adapt to diverse coil requirements with minimal setup time and easy digital operation.

Safety and Energy Efficiency at the Forefront

Safety is paramount with features such as emergency stop and overload protection, while energy-efficient operation is ensured by automatic lubrication and an economical 2.5 kW power consumption. The machines air cooling system and low noise emissions contribute to a user-friendly and environmentally considerate workspace, keeping productivity high without compromise.

FAQs of Affordable Vertical Winding Machines:

Q: How does the vertical winding machine ensure safe operation during use?

A: The machine is equipped with safety features including an emergency stop button and overload protection, allowing operators to quickly halt the machine or prevent damage, safeguarding both users and equipment.Q: What applications are best suited for this winding machine?

A: This winding machine is ideal for coil winding in the electrical, textile, and general industrial sectors, particularly where precise and consistent winding is essential. It supports wire sizes from 0.2 to 4 mm, making it suitable for a range of coil designs.Q: When should automatic lubrication be utilized, and how does it benefit the process?

A: Automatic lubrication is active during machine operation, ensuring that moving parts remain properly lubricated without manual intervention. This minimizes wear, extends equipment lifespan, and helps maintain consistent winding quality.Q: Where should the machine be installed for optimal performance?

A: As a floor-mounted unit with dimensions 1200x800x1700 mm and weighing 450 kg, the machine should be installed on a sturdy, level floor with adequate ventilation to support air cooling and ensure stable, vibration-free operation.Q: What process controls does the machine offer for customized winding tasks?

A: The PLC-based digital display allows operators to set and monitor winding parameters, adjust speeds between 1000 and 1500 rpm, select single or double winding heads, and optimize for different coil sizes effortlessly, ensuring flexibility across projects.Q: How can users benefit from the machines servo motor drive system?

A: The servo motor drive delivers precise speed and tension control for wire winding, resulting in high-quality, defect-free coils. It also enhances responsiveness and energy efficiency during the winding process.Q: Which industries most commonly use this winding machine?

A: Predominantly, it serves exporters, manufacturers, and suppliers in India within the electrical industry, but its design also makes it well-suited for textile and industrial winding applications requiring reliable, computerized coil production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Power Transformers Category

Roll Type Tension Stand

Drive Type : Other, Motorized

Material : Other, Alloy Steel

Automatic : Other, Fully Automatic

Product Type : Roll Type Tension Stand

General Use : Wire and Strip Winding Operations

Vertical Winding Machines

Drive Type : Other, Servo / AC Motor Driven

Material : Other, Mild Steel, Aluminium, and HighGrade Components

Automatic : Other, Fully Automatic Operation

Product Type : Vertical Winding Machine

General Use : Winding of Coils, Wire, and Filaments

Horizontal Winding Machines

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Material : Stainless Steel

Automatic : Yes

Product Type : Horizontal Winding Machines

General Use : Industrial

Power Winder Machines

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Material : Stainless Steel

Automatic : Yes

Product Type : Power Winder Machines

General Use : Industrial

Send Inquiry

Send Inquiry