Roll Type Tension Stand

Roll Type Tension Stand Specification

- Product Type

- Roll Type Tension Stand

- General Use

- Wire and Strip Winding Operations

- Material

- Alloy Steel

- Type

- Heavy Duty

- Weight (kg)

- Approx. 1200

- Computerized

- Yes

- Automatic

- Fully Automatic

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 4 kW

- Coil Diameter

- Up to 900 mm

- Winding Head

- Dual Head

- Winding Speed

- Variable up to 150 m/min

- Winding Spindle

- High Strength Steel

- Air Pressure

- 6 bar

- Drive Type

- Motorized

- Voltage

- 415 V AC

- Dimension (L*W*H)

- 2100 x 850 x 1600 mm

- Feature

- Consistent Tension Control for Accurate Winding

- Color

- Industrial Grey

- Safety Guard

- Provided

- Bearing Type

- Double Row Spherical

- Cooling System

- Air Cooling

- Roll Width

- 1100 mm

- Roll Diameter

- 250 mm

- Surface Finish

- Powder Coated

- Max Coil Weight

- 3500 kg

- Lubrication Type

- Automatic

- Maintenance

- Low

- Noise Level

- Low (<70 dB)

- Line Compatibility

- Cold Rolling, Galvanizing

About Roll Type Tension Stand

Note: As per the orders, we deliver them in promised time frame.

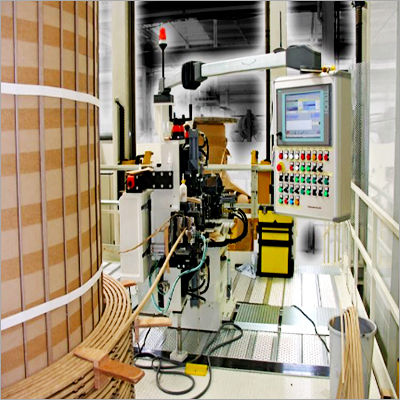

Robust Construction for Demanding Operations

Crafted from high-strength alloy steel and finished with durable powder coating, the Roll Type Tension Stand is designed to deliver reliable performance in high-demand industrial environments. Its heavy-duty structure, double-row spherical bearings, and high-strength winding spindle ensure consistent precision and extended service life, even during intensive wire and strip winding applications.

Precision Control with PLC Automation

Featuring advanced PLC-based controls and a fully automatic mechanism, this tension stand delivers exceptional accuracy during coiling. The dual-head winding, variable speed up to 150 m/min, and consistent tension management empower operators to achieve precise results for cold rolling and galvanizing lines, ensuring superior product quality and operational efficiency.

Safety, Efficiency, and Low Maintenance

Operator safety is prioritized with a robust safety guard and low noise output (<70 dB). The air-cooling system and automatic lubrication reduce required upkeep, while industrial-grade components minimize downtime. This ensures safer, more efficient workflows, reinforcing dependability for manufacturers and suppliers seeking optimal productivity.

FAQs of Roll Type Tension Stand:

Q: How does the Roll Type Tension Stand ensure consistent tension during the winding process?

A: The stand utilizes a PLC-based control system and a dual-head winding mechanism, which work together to maintain consistent tension. Automatic adjustments and high-strength components allow for precise and reliable winding, essential for achieving accurate coiling in industrial applications.Q: What types of operations is this tension stand suitable for?

A: This Roll Type Tension Stand is designed for wire and strip winding operations, particularly suited to cold rolling and galvanizing line processes. Its heavy-duty construction and high-strength materials make it ideal for industrial exporters, manufacturers, and suppliers handling demanding coil preparation tasks.Q: When should the Roll Type Tension Stand be used in a production line?

A: The stand is used during the coiling phase, where consistent and accurate winding tension is crucial. It is typically implemented after material processingsuch as cold rolling or galvanizingto prepare coils for storage, transportation, or subsequent manufacturing stages.Q: Where can this tension stand be installed?

A: The unit is suitable for installation in industrial facilities, specifically in wire and strip processing plants that employ cold rolling or galvanizing lines. Its compact dimensions (2100 x 850 x 1600 mm) and durable build support integration into existing or new production environments.Q: What is the process for maintaining the Roll Type Tension Stand?

A: This tension stand is equipped with an automatic lubrication system and features low-maintenance requirements. Routine visual checks for the bearings, safety guard, and general cleanliness are recommended, but the need for manual intervention is minimal due to its advanced automated systems.Q: How does the air cooling system benefit the tension stands performance?

A: The air cooling system helps manage operating temperatures, ensuring that the machine runs efficiently, even during prolonged use. This contributes to lower maintenance needs, enhances component longevity, and helps maintain a low noise level, improving the overall work environment.Q: What are the main benefits of using this stand for wire and strip winding?

A: Key benefits include precise tension control for accurate winding, low operating noise, high reliability, reduced manual maintenance, and robust safety features. These advantages result in higher productivity, superior coil quality, and greater operational safety for industrial producers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Equipments for Power Transformers Category

Vertical Winding Machines

Feature : Other, High Efficiency, Low Maintenance, Digital Counter, Emergency Stop

Drive Type : Other, Servo / AC Motor Driven

Automatic : Other, Fully Automatic Operation

General Use : Winding of Coils, Wire, and Filaments

Power Source : Electric

Affordable Vertical Winding Machines

Feature : Other, Easy Operation, Sturdy Construction, Energy Efficient

Drive Type : Other, Servo Motor Driven

Automatic : Other, SemiAutomatic/Automatic

General Use : Coil Winding for Electrical Industry

Power Source : Electric

Power Winder Machines

Minimum Order Quantity : 1 Piece

Feature : High Precision

Drive Type : Electric

Automatic : Yes

General Use : Industrial

Power Source : Electric

Horizontal Winding Machines

Minimum Order Quantity : 1 Piece

Feature : High Precision

Drive Type : Electric

Automatic : Yes

General Use : Industrial

Power Source : Electric

Send Inquiry

Send Inquiry