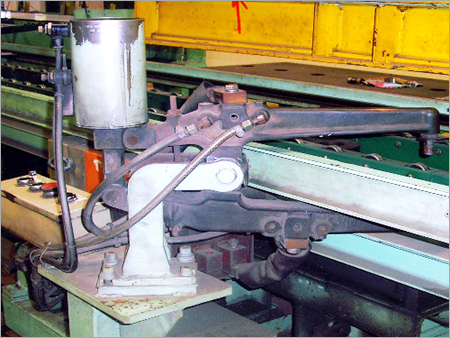

Multi Spotting Machine

Multi Spotting Machine Specification

- Product Type

- Multi Spotting Machine

- General Use

- Industrial stain removal

- Material

- Stainless Steel

- Type

- Spotting Machine

- Weight (kg)

- 80 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Push Button Control

- Power Source

- Electric

- Power Consumption

- 0.5 kW

- Air Pressure

- 5-7 Bar

- Drive Type

- Pneumatic

- Voltage

- 220 V

- Dimension (L*W*H)

- 1100 570 1350 mm

- Feature

- Efficient multi-spot application, anti-corrosive body

- Color

- White and Blue

- Application Area

- Garment, Textile, Laundry

- Noise Level

- Low Noise Operation

- Suction Motor

- High speed suction motor for quick drying

- Number of Guns

- 2 (steam & air) for different chemicals

- Foot Pedal Operation

- Yes

- Table Material

- Stainless Steel perforated table

- Mount Type

- Floor Standing

- Tank Capacity

- 2 L Each (chemical tanks)

- Heating Type

- Electric heating

- Safety Feature

- Overload motor protection

About Multi Spotting Machine

Leveraging on our rich industrial expertise and well known team of experts, we have been able to provide remarkable Multi Spotting Machine at competitive rates. This is appreciated for it's ergonomic design, dependability, optimum strength, easy installation, low maintenance needs, seamless quality, longer functional life, unmatchable performance, stability, simple operation, and many more.We are mainly deal this product in Hyderabad & it's near by areas.

- Multi Spotting Machine is built to perfection and in compliance with international norms of quality.

- As a result, this is widely used in textile industries.

Versatile Stain Removal Performance

Thanks to its dual-gun systemone for steam and one for airthe machine tackles a broad range of stains with different chemicals stored in separate 2L tanks. This flexibility ensures optimal results on a variety of fabrics, making it indispensable for garment and textile industries.

Robust and Practical Construction

Manufactured with a stainless steel perforated table and anti-corrosive body, durability and hygiene are guaranteed. The floor-standing mount, paired with a low-noise, high-speed suction motor, suits busy professional environments focused on efficiency and operator comfort.

Advanced Safety and User Convenience

Integrated overload motor protection and straightforward push-button controls prioritize operator safety and simplicity. The foot pedal operation offers hands-free convenience, streamlining processes and boosting productivity during industrial stain removal tasks.

FAQs of Multi Spotting Machine:

Q: How does the Multi Spotting Machine operate for stain removal?

A: This machine uses two separate gunsone for steam and one for airenabling targeted removal of various stains. Operators can select and apply the appropriate chemical or cleaning agent from dual 2L tanks, while high-speed suction dries the spot quickly, making the process highly effective.Q: What chemicals can be used in the machines tanks?

A: Each 2-liter tank is designed to handle a range of standard laundry and textile spot-removal chemicals, provided they are compatible with stainless steel. Always consult chemical guidelines and the manufacturers recommendations to ensure safe and optimal use.Q: When should I use the steam gun versus the air gun?

A: The steam gun is ideal for loosening and removing stubborn stains or dissolving residues, while the air gun assists in blowing away debris or drying treated areas quickly. Use either gun as appropriate to the stain type and fabric sensitivity.Q: Where is this machine best utilized?

A: This spotting machine is perfect for industrial settings such as garment manufacturing, textile cleaning units, and professional laundries. Its robust features and efficiency cater to high-volume or specialized stain treatment operations.Q: What is the process for operating the machine safely and efficiently?

A: Begin by loading the appropriate chemicals, ensuring the tank caps are sealed. Plug in the unit, set the desired pressure (57 bar), and use the foot pedal for activation. Select the right gun, apply the agent, and use the suction table for quick drying. Always monitor motor load and use the push-button controls for safe handling.Q: What are the benefits of the stainless steel perforated table and anti-corrosive body?

A: The stainless steel perforated table allows thorough drainage and airflow, enhancing stain removal efficiency. Its anti-corrosive properties extend the machines lifespan, making it suitable for frequent use in demanding environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

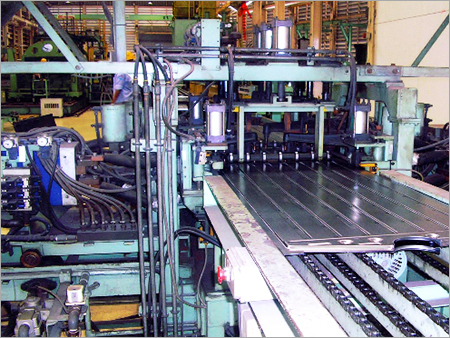

More Products in Radiator Manufacturing Line Category

De Coiler Machine

Product Type : De Coiler Machine

Computerized : No

Feature : Other, Heavy Duty, High Load Capacity, Precision Uncoiling, Adjustable Speed

Dimension (L*W*H) : 2300 x 1100 x 1800 mm (approx)

Material : Other, Mild Steel

Drive Type : Other, Motorized

Pre Spotting Equipment

Product Type : Pre Spotting Equipment

Computerized : No

Feature : Other, High pressure spray for stain removal, Compact design, Easy to operate

Dimension (L*W*H) : 450 x 450 x 1200 mm

Material : Other, Stainless Steel with Plastic Fixtures

Drive Type : Pneumatic

Send Inquiry

Send Inquiry