De Coiler Machine

De Coiler Machine Specification

- Product Type

- De Coiler Machine

- General Use

- For uncoiling and feeding sheet metal coils

- Material

- Mild Steel

- Type

- Automatic Decoiler

- Weight (kg)

- Approx. 1200 - 1500 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 3-7 kW (depending on model)

- Coil Diameter

- 450 mm - 1600 mm (adjustable)

- Winding Head

- Single/Double (as per requirement)

- Winding Speed

- 5-20 m/min (adjustable)

- Winding Spindle

- Heavy Duty

- Air Pressure

- 6-8 Kg/cm

- Drive Type

- Motorized

- Voltage

- 220V/380V/415V, 3 Phase

- Dimension (L*W*H)

- 2300 x 1100 x 1800 mm (approx)

- Feature

- Heavy Duty, High Load Capacity, Precision Uncoiling, Adjustable Speed

- Color

- Blue & Silver

- Max Coil Weight

- 5000 kg

- Expansion Range of Mandrel

- 480 mm - 530 mm

- Max Coil Width

- 1250 mm

- Noise Level

- 80 dB

- Brake System

- Pneumatic Disc Brake

- Mandrel Type

- Manual/Hydraulic Expandable

- Application

- Sheet Metal Processing, Roll Forming, Cut to Length Lines

- Surface Treatment

- Powder Coated

- Safety Feature

- Emergency Stop Button, Overload Protection

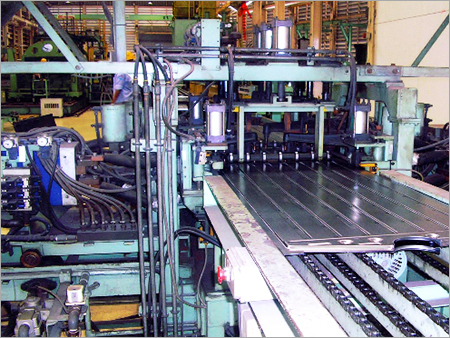

About De Coiler Machine

In order to meet the various requirements of the clients with the best products, we are offering commendable De Coiler Machine at most affordable prices. This is made using latest technology, techniques and superior grade raw materials, which are obtained from reliable vendors. Moreover, it is checked on multiple parameters like; design, construction, performance, efficiency, strength, etc to ensure consistent quality. Due to all, we are acknowledged as market oriented supplier, manufacturer and exporter.We are mainly deal this product in Hyderabad & it's near by areas.

Note: We manufacture De Coiler Machine in allotted time limit.

High Precision & Heavy Duty Performance

Designed to handle up to 5000 kg coil weight, the De Coiler Machine ensures precise and smooth uncoiling with minimal noise. Its robust construction, adjustable winding speed, and heavy-duty spindle facilitate consistent feeding of sheet metal coils for high-output manufacturing lines. Operators benefit from efficient sheet handling and customizable settings.

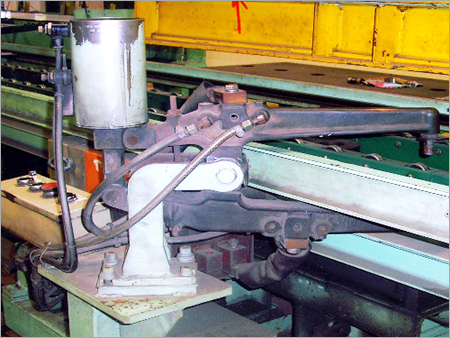

Advanced Safety and Control Systems

Safety is a priority with this de coiler, offering emergency stop functionality, overload protection, and a pneumatic disc brake system. Its PLC-based control panel allows straightforward and reliable operation, reducing the risks associated with uncoiling heavy materials. This makes the machine suitable for continuous and automated production environments.

Versatile Application and Customisation

The De Coiler Machine is suited for roll forming, cut-to-length lines, and sheet metal processing, accommodating various coil widths, thicknesses, and materials. With single or double winding head options and a manual or hydraulic mandrel, users gain flexibility for diverse configurations and operational needs, making it a valuable asset for manufacturers, suppliers, and exporters in India.

FAQs of De Coiler Machine:

Q: How does the De Coiler Machine operate and what are its main features?

A: The De Coiler Machine operates by securely holding and unwinding sheet metal coils using a heavy-duty, motorized spindle, and an expandable mandrel. Key features include a maximum coil width of 1250 mm, coil weight capacity of 5000 kg, PLC-based controls, adjustable speed (520 m/min), and a pneumatic disc brake for smooth, controlled stopping.Q: What types of sheet metal processing applications can this machine handle?

A: This machine is ideal for sheet metal processing tasks such as roll forming, cut-to-length lines, and general uncoiling operations. Its robust design and configurable options (manual/hydraulic mandrel, single/double winding head) make it suitable for a range of industrial uses requiring precision uncoiling and high load capacity.Q: When should I use the emergency stop or overload protection features?

A: The emergency stop button should be used anytime an unsafe situation arises, such as tangling or jamming of the sheet metal. The built-in overload protection automatically halts operation if the load exceeds safe operating limits, safeguarding both the machine and operators.Q: Where can the De Coiler Machine be installed and what are the space requirements?

A: The De Coiler Machine is suitable for installation in industrial environments like manufacturing plants and metalworking factories. It requires an approximate floor space of 2300 x 1100 mm and a height clearance of 1800 mm, allowing for integration into existing sheet metal processing lines.Q: What is the process for adjusting the coil diameter and winding speed?

A: Coil diameter is adjusted using the manual or hydraulic mandrel expansion, with a range of 480 mm to 530 mm. Winding speed can be set between 5 and 20 m/min via the PLC-based control panel, providing flexibility to match various processing requirements.Q: How does the machine benefit sheet metal manufacturers and suppliers?

A: The De Coiler Machine enhances efficiency and productivity by enabling smooth, precise feeding of sheet metal into automated production lines. Its heavy-duty construction, high load capacity, and safety systems improve operational reliability, reducing downtime and maintenance for manufacturers and suppliers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Radiator Manufacturing Line Category

Multi Spotting Machine

Feature : Other, Efficient multispot application, anticorrosive body

Type : Other, Spotting Machine

Automatic : Other, SemiAutomatic

Air Pressure : 57 Bar

Material : Stainless Steel

Control System : Push Button Control

Pre Spotting Equipment

Feature : Other, High pressure spray for stain removal, Compact design, Easy to operate

Type : Other, Laundry PreSpotting / Stain Removing Machine

Automatic : Other, No (Manual Operation)

Air Pressure : 46 bar

Material : Other, Stainless Steel with Plastic Fixtures

Control System : Manual Control with spray trigger

Send Inquiry

Send Inquiry