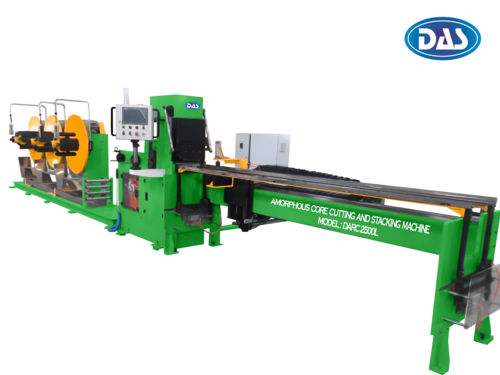

Amorphous Core Cutting and Stacking Machine

Amorphous Core Cutting and Stacking Machine Specification

- Drive Motor

- AC Servo motor

- Product Type

- Core Cutting and Stacking Machine

- General Use

- Transformer core manufacturing

- Material

- Amorphous metallic strip

- Type

- Fully Automatic Machine

- Capacity

- Up to 60 cores/hour

- Weight (kg)

- 1900 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- Cutting Speed

- 60-120 cuts per minute

- Cutting Thickness

- 0.03 0.35 mm

- Cutting Function

- Automatic feeding, cutting, and stacking

- Cooling System

- Industrial air cooling

- Drive Type

- Servo motor driven

- Voltage

- 380V / 50Hz

- Dimension (L*W*H)

- 2350 x 1800 x 1700 mm

- Feature

- High precision, high efficiency, minimal burrs

- Color

- As per customer requirement / standard gray

- Motor

- 3 kW servo motor

- Mechanical Precision

- 0.1 mm

- Software Detail

- PLC based control with touchscreen interface

- Cutting Method

- Shearing / Blade Cut

- Control System

- Touchscreen PLC

- Cutting Area

- 300 mm x 300 mm

- Cutting Material

- Amorphous metal strip

- Ambient Temperature Range

- 5C to 40C

- Max Strip Width

- 300 mm

- Maintenance

- Low, easy access panels

- Applicable Standards

- CE Certified

- Stacking Method

- Automatic with layer alignment

- Min Cut Length

- 30 mm

- Installation Mode

- Floor mounted

- Feed Accuracy

- 0.05 mm

- Operation Mode

- Continuous or manual

- Cutting Tolerance

- 0.15 mm

- Safety Feature

- Emergency stop & interlocks

- Power Consumption

- 6 kW

- Noise Level

- 75 dB

Amorphous Core Cutting and Stacking Machine Trade Information

- Sample Available

- Yes

About Amorphous Core Cutting and Stacking Machine

Technical Specification

| Specifications | Size |

| Ribbon Cutting Sizes: | |

| Width of Ribbon: | 140 to 250mm. |

| Min/Maximum cutting length of ribbon: | 300/2500mm |

| Platform working length: | 2800mm |

| Number of cuts/hour. | 360(Including feeding of max. length of sheet) |

| Shearing Length: | 300-2500mm |

| Max. Stacking height: | 220mm |

| Accuracy of Cutting and Stacking: | |

| Cutting Accuracy: | +/-1mm |

| Position Accuracy: | +/-1mm |

| Productivity: | |

| Feeding Speed: Type: Feed Roller with servo motor. | 120mts/min max. |

| Shearing Speed: By Electromechanical: | 45stokes/min |

| Cycle time for 1000mm long ribbon cutting: | 4sec. |

| Decoiler: | |

| Spool Inside Diameter: | 360-430mm |

| Spool Outside diameter: | 1200mm |

| Max.Carrying weight of Un-Coiler: | 1100kgs. |

| Un-coiling speed: | 0-100rpm |

| Speed Control | By VFD |

| Operating Mode: | Manual Or Auto; through line sensor signals. |

| Spool Clamping: | Manual. |

| PLC | Mitsubishi/Omran. |

| Touch Screen | Mitsubishi/Omran. |

| Pneumatics | SMC/Festo. |

| Requirements | |

| Power supply | 25HP/3ph; 50HZ |

| Air supply | 6bar min |

| Flore space | 12000Lx3200wx2200H |

| Weight of machine | 6000kg(Approximate) |

Unmatched Precision and Efficiency

Equipped with servo motor drives and PLC-based touchscreen control, this machine ensures consistently accurate cutting and stacking of amorphous metal strips. Achieve a feed accuracy of 0.05 mm and produce high-quality cores with minimal burrs, maximizing manufacturing yield.

Comprehensive Safety and User-Friendly Operation

The machine is floor-mounted and includes emergency stop and safety interlocks, prioritizing operator protection. Its intuitive color touchscreen interface streamlines operation, allowing manual or continuous modes for optimal workflow flexibility.

Designed for Reliability and Low Maintenance

Engineered for industrial durability, the system supports quick, easy access for maintenance, reducing downtime. The robust cooling system and protective features keep the machine performing reliably, with low servicing needs and compliance to CE standards.

FAQs of Amorphous Core Cutting and Stacking Machine:

Q: How does the Amorphous Core Cutting and Stacking Machine ensure precise cuts?

A: The machine combines servo motor drives and PLC-based controls to achieve and maintain feed accuracy of 0.05 mm and cutting tolerance 0.15 mm, ensuring every strip is processed to exact specifications with minimal burr formation.Q: What is the process for operating this machine?

A: Operation begins by loading the amorphous metallic strip onto the feeder. The PLC touchscreen interface allows you to select continuous or manual mode. The machine automatically feeds, cuts via shearing blade, and stacks cores with layer alignment until the desired quantity is produced.Q: Where is the Amorphous Core Cutting and Stacking Machine typically installed?

A: This equipment is designed for floor-mounted installation in facilities manufacturing transformer cores, export, supply, and production areas in India or internationally. Its dimensions (2350 x 1800 x 1700 mm) suit most industrial spaces.Q: What are the benefits of using this machine in transformer core production?

A: Users benefit from high-precision cuts, reliable stacking alignment, fully automatic operation, increased productivity (up to 60 cores/hour), low noise levels, and minimal maintenance requirements, resulting in efficient and high-quality core manufacturing.Q: How is safety addressed in the machines design?

A: The machine incorporates emergency stop functions and multiple interlocks to protect personnel. These features, combined with the PLC touchscreen for controlled operation, ensure a safe working environment during both continuous and manual processes.Q: What is the recommended operating environment for this machine?

A: For optimal performance, the machine should be used within an ambient temperature range of 5C to 40C, ensuring stable operation and long equipment life in most industrial environments.Q: Can the machine be customized based on customer requirements?

A: Yes, the outer color can be supplied as per customer preference, along with standard gray. Its PLC software can also be tailored to meet specific workflow needs in core manufacturing operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CRGO Core Cutting Machine Category

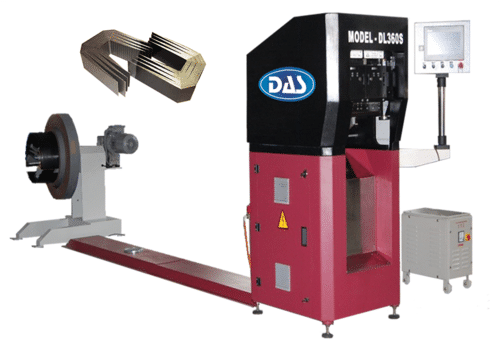

Wound Core Cutting Mahchine

Price 47000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Feature : Other, High Precision Cutting

Computerized : Yes

Voltage : 220V/380V

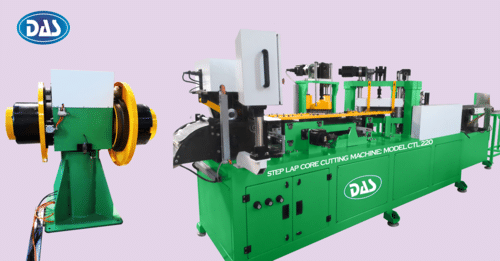

Rectangular Core Cutting Machine

Price 47000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Feature : Environmental Friendly

Computerized : No

Voltage : 220240 Volt (v)

Crgo Core Cutting Machine

Price 60000 USD ($) / Unit

Minimum Order Quantity : 1 , , Piece

Warranty : 1 Year

Feature : Good Quality

Computerized : No

Voltage : 220240 Volt (v)

Send Inquiry

Send Inquiry